Kuvala kwa saladi ya Industrial /Mayonnasie Homogenizing Tank

ZOKHUDZA KWAMBIRI

Kapangidwe kake ndi kosavuta, magwiridwe ake ndiosavuta, ndipo kutalika kwa makina onse ndikopulumutsa malo. Zida zophatikizira zapamwamba zimatsimikizira mtundu wa yunifolomu yazamalonda. Njirayi ili ndi ntchito zosiyanasiyana ndipo imatha kufananizidwa ndimapangidwe osiyanasiyana, monga zingalowe m'malo, kutentha kwa jekete / kuzirala, mawonekedwe otsegulira ketulo, kapangidwe kazitsanzo, etc. Zonsezi zimapangitsa zida izi kukhala zida zabwino zopangira zinthu zamadzimadzi. Dongosololi limasinthasintha kapangidwe kake ndipo limatha kusinthidwa ndikusinthidwa malinga ndi zosowa za ogwiritsa ntchito m'mafakitale osiyanasiyana.

Mawonekedwe ndi Njira zoyambira

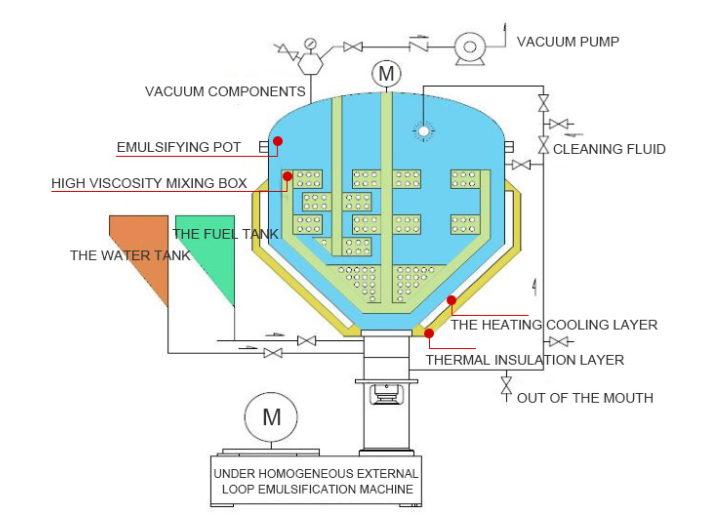

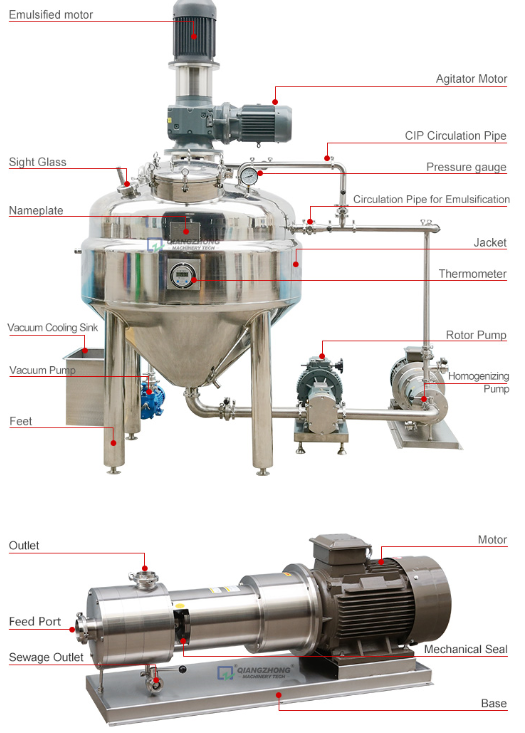

Makina akunja oyendetsa homogenization ndiye maziko, omwe amaphatikiza ntchito zingapo zokoka, kupopera, kupezeka, ndi kuyeretsa kwa CIP. Thupi la mpope wamagawo awiri limalola kuti dongosolo la homogenization lingopereka mphamvu yakusakanikirana ndi zinthu, komanso limapatsanso kuthekera kwamphamvu, komwe kulinso koyenera kwa zida zowoneka bwino kwambiri. Makina akunja oyendetsa homogenization amalola gawo lamadzi ndi gawo lamafuta kuti lizisungunuka mwachindunji mu kachitidwe ka homogenization kenako ndikupopera ku riyakitala yoyambitsa, yomwe ingapewe zolakwika ndi zofooka za chikhalidwe.

Imeneyi ndi njira yabwino yomwe imaphatikizira kutulutsa kothamanga kwambiri, kufanana kwa zinthu zopanga tinthu kukula, komanso kukhathamiritsa kwambiri kwa emulsification ndi homogenization. Madzi olimba amatha kuwonjezeredwa mwachindunji pamutu wopatsa mphamvu, ndipo amatenthedwa msanga komanso kwathunthu ndikubalalika kuti apewe kuphatikiza. Pakutsuka kwa CIP, mawonekedwe ampope oyenda kunja a emulsification atha kugwiritsidwa ntchito ngati mpope woperekera kuti apereke madzi othamanga kwambiri pa CIP yoyenda kupopera mpira.

1. Magawo osakanizidwa komanso omwazika amawonjezeredwa mwachindunji kumutu wogwira ntchito.

2. Kamangidwe yodziyimira payokha ya kukoka ndodo ndi yabwino yokonza ndi disassembly.

3. Kuyenda kwazinthu, kuyeretsa ndi kutulutsa kwa CIP sikutanthauza mapampu ena.

4. Sankhani momasuka ngati nkhaniyo imadutsa pamalopo.

5. Kuchita bwino ndikukonzekera nthawi yayifupi.

Makina oyambira emulsification amatha kukhala ndi zida zosiyanasiyana zodyetsera, akasinja am'mapapo am'mbuyomu ndikuwononga akasinja oyimitsa. Malinga ndi zosowa, zida zosiyanasiyana zotenthetsera kapena zoziziritsira zitha kuwonjezeredwa. Nthunzi ingalowetsedwe mwachindunji muapaipi yoyendetsera zinthuzo.

Makina oyang'anira zamagetsi amathanso kusinthidwa, kuphatikiza kuwongolera kosavuta kwa batani ndi pulogalamu yolumikizira ya PLC yokhala ndi zowongolera. Titha kuperekanso zida zamagetsi kapena zodziwikiratu momwe zingafunikire.

Poyerekeza ndi mtundu womwewo wa zida zakunja, makina athu ochezeka amatha kukwaniritsa zosowa zamakasitomala malinga ndi magwiridwe antchito komanso itha kuperekanso kuyesa kosavuta kwamachitidwe. Tilinso ndi zabwino zambiri kuposa iwo potengera nthawi yoperekera mtengo komanso ntchito yogulitsa pambuyo pake.